What is UAO?

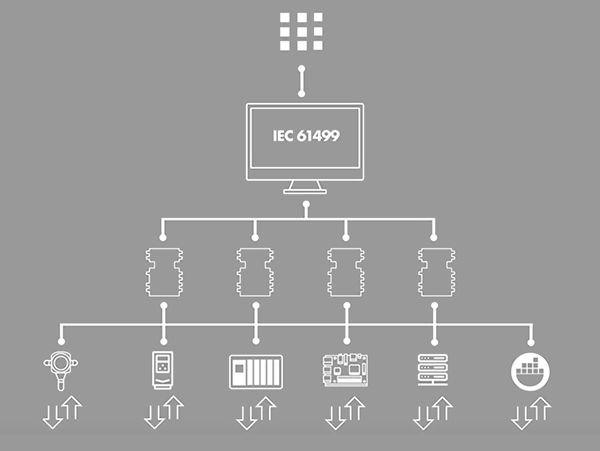

UniversalAutomation.org is an independent, non-for-profit association managing the implementation of an industrial automation shared source runtime execution engine, based on the IEC 61499 standard.

This new level of shared technology provides the basis for an ecosystem of portable, interoperable, “plug and produce” solutions and creates an entirely new category within industrial automation. UniversalAutomation.org is open to new members looking to advance the world of automation.

Brief history

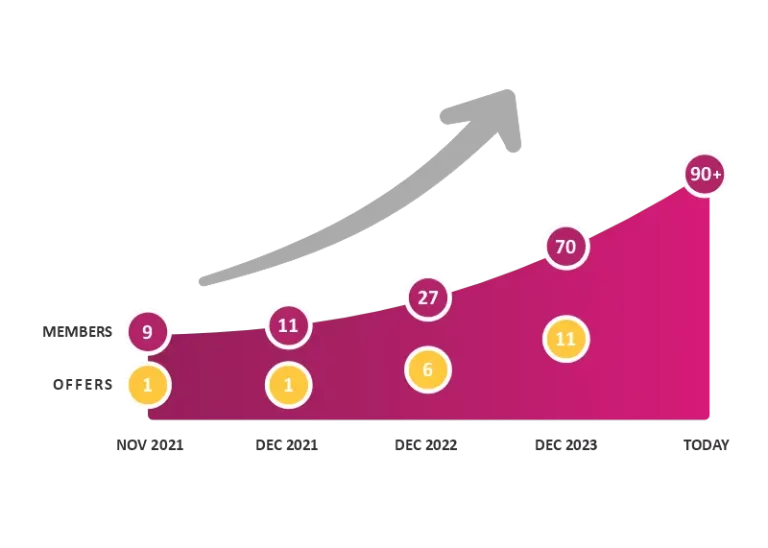

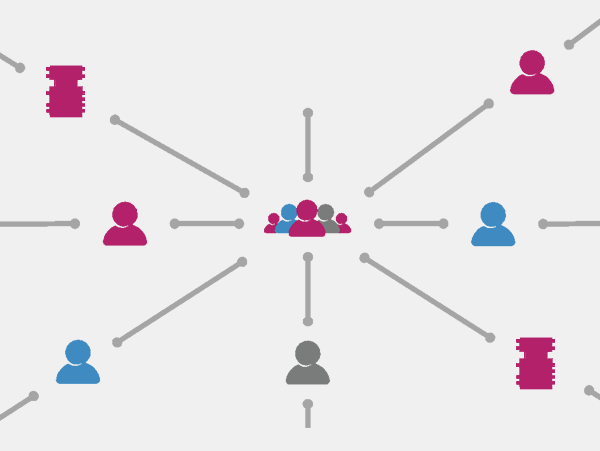

UniversalAutomation.org was officially established in November 2021 by 9 founding members representing both the user and vendor communities:

These visionaries initiated our journey, which has now expanded to more than 90 members, encompassing automation users, technology vendors, academics, institutions, and startups. Simultaneously, technology vendors members are introducing market offerings featuring the UAO runtime execution engine, thereby advancing the universal automation solutions market.

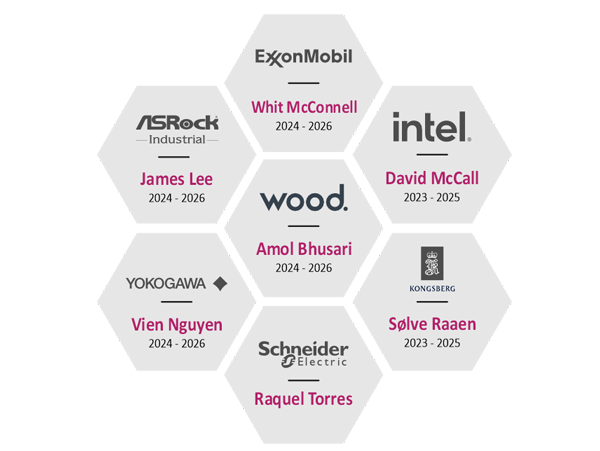

Board of Directors

James Lee

Chairman | ASRock Industrial

Whit McConnell

Chief Engineer | Automation & Process Control at ExxonMobil

David McCall

Senior Director | Industrial Standards at Intel Corporation

Sølve Raaen

Principal Architect | Kongsberg Maritime

Raquel Torres

Chief Ecosystem Officer | Schneider Electric

Vien Nguyen

Principal Software Architect | Yokogawa

Amol Bhusari

Business Manager | Digital Integration at Wood

Industry Leaders Found UniversalAutomation.org to Launch New Automation Era

Industrial leaders and pioneers have joined together to form UniversalAutomation.org (UAO) and advance the world of industrial automation.

For the first time, vendors, users and academics will share a common automation software layer across their automation technology regardless of brand. This technological collaboration is driving the development of an ecosystem of portable, interoperable, “plug and produce” solutions, creating an entirely new category of industrial automation.

Portability is already a reality in other market sectors

Portability is already a reality in other market sectors. For example, mobile applications are developed to run across different smartphone vendors, enabling rapid advances through collective innovation. Until now, the industrial world has worked differently, with closed proprietary architectures and hardware-dependent software.

UniversalAutomation.org will create a new era of openness and collaboration, decoupling software and hardware by sharing a reference runtime execution engine implementation of the IEC 61499 standard.

Members are working together

Members are working together to develop and adopt the next generation of universal automation solutions by collectively incrementing a runtime execution engine following shared source principles. Improvements to the runtime are managed by UniversalAutomation.org and its members. Development of prioritized features will be financed by UniversalAutomation.org or contributed by members. Members will have access to the runtime and the ability to shape the next generation of automation.

This shared runtime execution engine approach not only accelerates the adoption of the technology; it also maximizes portability by standardizing on a common runtime platform. It is the technology enabler of the future world of plug and produce industrial automation apps.

UniversalAutomation.org is actively recruiting new members. All entities looking to help advance industrial automation are encouraged to join.

Industry advancement with interoperable automation software

Adopting a common runtime execution engine, shared across vendors, will provide limitless opportunities for growth and modernization across industry. The ARC Advisory Group found this move could save the industrial market $30 billion each year, which is currently spent servicing and maintaining the installed base of proprietary systems alone.

UniversalAutomation.org members anticipate the adoption of this reference implementation-based approach to industrial automation to deliver a range of benefits, including:

- Portability and reuse of software components on different systems, improving return-on-investment for automation application software

- Greater Innovation through the faster integration of IT and OT technologies and systems, development of new business models, easier connectivity, and more flexible/modular production systems to meet rapidly changing market requirements

- Hardware-independent software applications, that can be distributed to and interoperate across multi-vendor platforms

- Extending the lifespan of existing industrial tools, devices and systems, and easier upgrading of systems reaching their end of life

- Simplified training and skills (with teams only needing to learn one common system), making automation industry OT entry more accessible to IT professionals and the new generation of automation professionals

- Increased reliability and reduced time to market using proven in use plug and produce software components available on AppStore-like platforms

The creation of UniversalAutomation.org is the dawn of a new era within automation technology

Dmitrii Drozdov Chief Technology Officer at Flexbridge