Frequently Asked Questions

About UniversalAutomation.org

UniversalAutomation.org current members include a diverse group of industrial leaders and pioneers – including hardware & software technologyvendors, end users, systems integrators, OEMs, start-ups and higher education institutions.

Members develop and adopt the next generation of universal automation solutions — software components that bring unique values to users, based on the IEC 61499 standard. They also increment a shared runtime and champion its use. Members have access and the ability to shape the runtime implementation.

Applications for membership are open to all, everyone is encouraged to join.

UniversalAutomation.org has been formed by a diverse group of industrial leaders and pioneers who have joined together to advance the world of industrial automation.

For the first time, hardware & software technology vendors, end users, systems integrators, OEMs, start-ups and higher education institutions will share a common automation software layer across their products and solutions—regardless of brand. This new level of shared technology provides the basis for an ecosystem of portable, interoperable, “plug and produce” solutions and creates an entirely new category within industrial automation.

UniversalAutomation.org members will develop interoperable and portable automation software – based on the IEC 61499 standard – that can run with almost any hardware, creating an entirely vendor-agnostic ecosystem for automation software development. By merging both the information technology and operational technology worlds and sharing a technology reference implementation, the organization seeks to unleash the full potential of Industry 4.0.

Current industrial automation system architecture has done a good job of advancing industry to where we are today. However, “open automation” as it exists today is not enough. Industry-wide adoption of universal automation will ensure next-generation software applications are interoperable and portable.

We have already seen other industries thrive from adopting interoperability, including the IT, energy, and telecoms spaces, and the time is now to ensure we don’t stay behind. Our industry has long been on the edge of disruption, attempting to fulfil the promise of the Fourth Industrial Revolution.

Today, the current health emergency along with ever-changing global market dynamics have underlined the need for resilience and agility, which can only come from digitization that includes interoperable industrial automation applications. It is time to embrace interoperability and abandon proprietary systems to meet today’s and tomorrow’s demands. We intend to give industrial enterprises the ability to choose best-of-breed solutions that suit their unique needs and effectively address modern challenges.

Today, we must come together and innovate to drive sustainable and long-lasting positive change for our industries.

UniversalAutomation.org is a complementary partner to the other initiatives aiming at a more open automation world.

UniversalAutomation.org is not creating a new standard. UniversalAutomation.org is managing a reference runtime implementation of the IEC 61499 standard on a shared source basis.

The IEC 61499 standard defines interoperability at the application level and does not specify any communication protocol.

The IEC 61499 runtime shared by UniversalAutomation.org already has an OPC UA stack implemented. The initiatives of UniversalAutomation.org and the OPC Foundation are complementary.

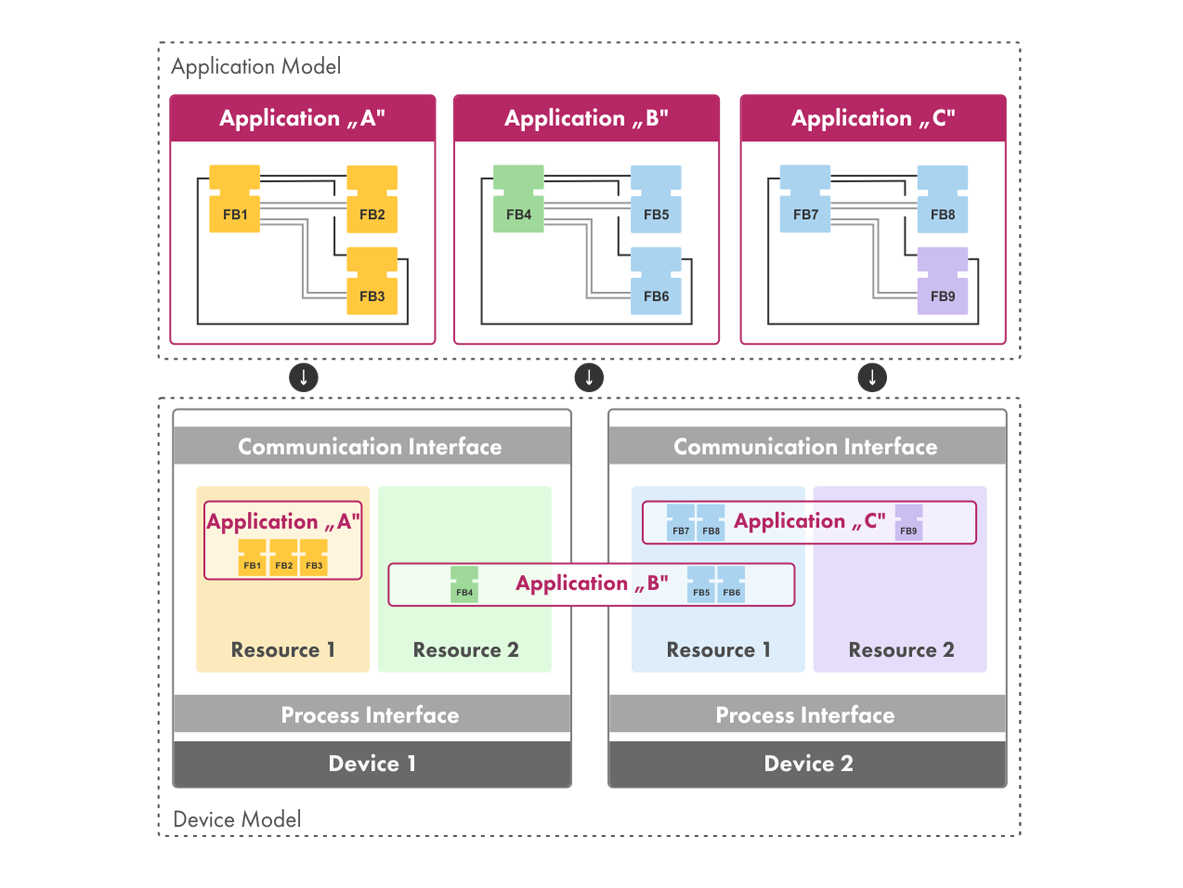

IEC 61499 allows one or multiple applications to be run on one resource/device or distributed to multiple resource/devices.

IEC 61499 allows one or multiple applications to be run on one resource/device or distributed to multiple resource/devices.

If an application is split and distributed to multiple resource/devices, all cross communications between the application’s FB’s on different resources/devices are automatically re-created & managed by the UAO runtime. This is what we mean by application interoperability – the ability to split connected FB’s in an application and have them interoperate across the different resource/devices to which they are distributed.

UniversalAutomation.org is not a standardization organization but is sharing a reference implementation of a runtime execution engine based on the IEC 61499 standard.

Every company, academia, institutes and start up can apply to join the non -profit association UniversalAutomation.org

UAO does not have its own IDE, but can support vendors with the developments of their own IDE providing a IEC 61499 compliance profile.

UAO is sharing a reference implementation of IEC 61499 standard accelerating and promoting the use of the standard. The standard is maintained and managed by a dedicated IEC steering committee.

UAO accelerates the implementation and adoption of the IEC 61499 standard though a shared source model of the reference implementation.

UAO’s mission is to maintain, further develop, and manage a reference runtime implementation based on IEC 61499 to enable portable, interoperable, “plug and produce” applications across vendor hardware, powering an open, software‑defined automation era.

Members can vote on general matters, influence the runtime roadmap (via tier‑dependent roadmap voting rights), sit on advisory boards, join working groups, and network with users and vendors to accelerate adoption.

Academics

Academic Partners can access the IEC 61499 Curriculum developed by UniversalAutomation.org. For more details, please visit: Academic Partners with IEC 61499 Curriculum

Academic members can contribute to the runtime development, curriculum content, encourage students to create application examples and collaborate with industries for joined projects.

UAO developed a full turn-key IEC 61499 curriculum that Academics worldwide have been implementing.

For a comprehensive overview of the IEC 61499 standard, please refer to the Curriculum available on the UAO Portal.

Academics can exchange between themselves but also with industries using the UAO community meetings and regular events organized by the association.

On the UAO website, you can find the list of UAO Academic partners involved into IEC 61499 activities

UniversalAutomation.org is striving interactions between all member types, especially academics. For example, they can share their researches linked with IEC 61499 with the industrial community, get networking oppportunity for common reasearch projects, internships, events …

UniversalAutomation.org provides a curriculum to teach about the IEC 61499 technology.

Professor are flexbile to decide which way they want to build their own courses. The association and community are there to support them.

Business model

No, apart from the yearly membership fee, device vendors are not required to pay royalties for every UAO device sold.

Yes, UAO supports other IDEs to enable them to deploy to the UAO runtime execution engine

No royalty is to be paid back to UAO for every devices sold by a device vendor. UAO members that are device vendors can sell any number of devices just by paying the yealry membership fee that gets them access to the UAO runtime source.

Technology vendors receive support from UniversalAutomation.org and get trained on porting the Runtime to their own platform.

Its Shared Source model, where all UAO members that has access to UAO runtime source can use it and also contribute back.

Market benefits

You can start benefiting from UniversalAutomation.org right away.

Existing systems can be integratedinto the IEC 61499 environment by creating an orchestration layer running with equipment embedding the UniversalAutomation.org runtime.

Current industrial automation system architecture has done a good job of advancing industry to where we are today but “open automation” as it exists today is not enough. Industry-wide adoption of universal automation will ensure next-generation software applications are interoperable and portable.

The IEC 61499 standard extends and enhances the IEC 61131-3 standard. It solves the problems of ensuring portability, configurability, and interoperability of application software across vendors and, at the same time, permits software and hardware independence. It allows a seamless integration with the IT layer and an easy distribution of control logic.

The IEC 61499 standard is a technological enabler for a “plug and produce” approach to industrial automation. Adoption of a shared automation layer, common across vendors, will provide limitless opportunities for growth and modernization across industry. The confluence of digitization and the IEC 61499 standard now make it possible for such open systems to be easily and effectively deployed.

Yes. Universal automation and open industrial standards are fundamentally necessary to fulfil the promise of the Fourth Industrial Revolution. The pressure to adopt open automation is mounting for stakeholders across all corners of industry.

End users are beginning to see proprietary automation systems as a barrier to growth and an unnecessary cost, rather than an enabler and source of profit. Many organizations recognize that next-generation industrial automation must be interoperable and break free from the proprietary closed model we have now.

A few examples are: Open Process Automation Forum, NAMUR, and OPC Foundation.

Moving from a proprietary world to universal automation not only benefits end users but it also gives those willing to innovate an edge in the race for new value built on software innovation.

Universal automation will create a market for proven-in-use software components that bring unique values to users and new revenues for vendors.

The industry realizes that working to the same, open standards is fundamental to progress. Our ecosystem, from supply chain through manufacturing and production to the end customer, recognizes the need to fully embrace interoperable implementations.

Technical

For sure, the runtime is suitable to be ran in a container which could run for example on a server.

A ready-made version already exists (see Soft dPAC from Schneider Electric) and others will be soon developed by the vendor members.

Linux-based platforms and UAO are solving different problems.

The Linux-based automation platforms allow the User to do real-time control applications as well as run other applications using other programming languages like C++ or Python on the same computer platform. Although they are Linux-based, they remain proprietary because they implement proprietary techniques to guarantee real-time performance and determinism, namely real-time OS patches and standardized data layer access (including IO access) for all applications. So applications cannot be ported from one Linux platform to another one without significant rework and retest.

UAO provides a runtime execution engine for an event/data-based system environment (based on IEC 61499). The objective is to enable plug & produce applications that are independent of the hardware platform on which they execute. In other words, users can build applications using libraries of vendor-independent UAO software components, plugging them together using the event-data interface, and distributing the complete application to one or multiple Universal Automation controllers. The same application can be deployed to different platforms with no rework except for connecting the “logical” IO to the real physical IO of the new platform.

The two approaches are complimentary. UAO is available on several Linux-based platforms.

When a vendor joins UAO, it is his responsibility to verify and validate the offer that he launches on the market. And he is responsible to support his offer.

When it comes to project support, it is up to the application system integrator to guarantee and support the application for the user. In the event of issues with the UAO platform, the system integrator will rely on the UAO platform vendor for support. In the event that the issues are with the UAO runtime itself, the vendor will turn to UAO for support to resolve the issue if he is not able to resolve himself..

This approach is not new – many automation PLC vendors use 3rd party software products for their IEC 61131 software, and most project applications are provided by independent system integrators.

The following options are currently available:

- Schneider Electric – EcoStruxure Automation Expert IDE (See DEMO)

- Aimirim – 4diac IDE plugin (with the limitations described in the plugin documentation) (See UAO Live DEMO)

Vendor “A” UAO device can be replaced with Vendor “B” UAO device and the same application can be re-deployed and run without any changes with one exception. The exception is if a Service function block that is specific to hardware of Vendor “A” device is used in application, then it must be ensured that the Vendor “B” device also supports it.

UAO Runtime is shared with its members as Source code, not as an Software Development Kit, a set of libraries, as an installable or as an executable package. The members are at liberty to choose whichever form they want to give it. It can be compiled and run as an embedded process on a physical controller, can be run as an application or process on any computer with an OS or an RTOS, and it can be also run inside a docker-container or Kubernetes etc..

UAO Runtime is shared with its members as Source Code, not as an Software Development Kit, a set of libraries, as an installable or as an executable package. The members are at liberty to choose whichever form they want to give it. It can be compiled and run as an embedded process on a physical controller, can be run as an application or process on any computer with an OS or an RTOS, and it can be also run inside a docker-container or Kubernetes etc..

The UniversalAutomation.org runtime has been package in a scalable way to adapt to most platforms depending on their operating system, CPU and memory size. Getting an offer which embeds the runtime could take only a few months.

UAO runtime is shared with its members as Source code, not as an Software Development Kit, a set of libraries, as an installable or as an executable package. The members get access to the source code on the UAO GitHub.

UAO runtime is a shared implementation of the IEC 61499 standard aimed at portability and interoperability at the core against Virtual PLCs that are still vendor-specific requiring additional efforts for interoperability. UAO runtime is scalable and can be run in any mode, as an embedded process, as a container, and as a virtual PLC.

UAO runtime is shared with its members as Source code, not as an Software Development Kit, a set of libraries, as an installable or as an executable package. The members are at liberty to choose whichever form they want to give it.

It can be compiled and run as an embedded process on a physical controller, can be run as an application or process on any computer with an OS or an RTOS, and it can be also run inside a docker-container or Kubernetes etc..

No. IEC 61499 is a system‑level design language for distributed information and control systems. It defines event‑driven function blocks, application, device/resource models, and system mapping, enabling hardware‑independent application portability.

Linux platforms solve co‑location of control and other apps on the same box but often remain proprietary for determinism and data access. UAO provides a vendor‑independent runtime enabling event/data‑driven applications to be portable across different platforms; both approaches are complementary and UAO is available on several Linux platforms.

When an IEC 61499 application is distributed across multiple devices/resources, the runtime automatically recreates and manages cross‑communications between the connected function blocks, delivering application‑level interoperability.

Scope & Core Idea:

- SDA (market): A broad industry movement to decouple control from hardware and bring IT practices (virtualization, edge/cloud, CI/CD) into OT

- UAO: An independent, non‑profit association managing a shared‑source IEC 61499 runtime to enable portable, interoperable, “plug and produce” applications across multi‑vendor hardware.

Openness & Portability:

- SDA (market): Implementations are typically vendor‑centric platforms. They improve flexibility and IT/OT convergence, but application‑level portability across different vendors is not guaranteed and often depends on each supplier’s stack and standards choices.

- UAO: Delivers application‑level interoperability and portability via IEC 61499; when applications are distributed, the UAO runtime automatically manages cross‑device function‑block communications, making redeployment across UAO‑compliant devices practical.

Governance & Licensing:

- SDA (market): Governed by individual vendors or platforms; licensing terms vary and there is no single shared runtime across suppliers.

- UAO: Uses a shared‑source governance model under an IP Policy; source access depends on membership tier, and UAO does not charge per‑device royalties beyond annual membership.

Tooling & Engineering Workflow:

- SDA (market): Emphasizes DevOps‑style workflows (versioning, remote access, virtual PLC orchestration, browser‑based IDEs) to modernize PLC/automation engineering.

- UAO: Supports multiple IDEs (e.g., EcoStruxure Automation Expert, Eclipse 4diac plugin) and recommends wrapper function blocks to integrate legacy systems into an IEC 61499 orchestration layer.

Runtime Deployment:

- Both: Support modern execution models. UAO’s runtime can run embedded on controllers, as OS processes, in containers (Docker/Kubernetes), or as a virtual PLC.

Bottom line:

- SDA (market) modernizes automation with software‑first practices but remains implementation‑specific to each vendor.

- UAO provides open software‑defined automation anchored in a shared IEC 61499 runtime, delivering portable applications across multi‑vendor hardware under independent governance.