Join the team

changing the game!

For far too long proprietary automation systems have been restricting innovation. Joining UniversalAutomation.org means becoming part of a one-of-a-kind organization sharing a common technology that will unleash innovation by enabling application portability.

What is universal automation?

It is the combination of two parts: A technology enabler based on the IEC 61499 standard which defines how to design distributed applications using “plug and produce” software components which are independent from the hardware on which they execute. A community of automation users, technology vendors and academics organized around an independent non-profit association: UniversalAutomation.org.

UniversalAutomation.org is open to new members willing to change the game of automation.

Why join us?

Members of UniversalAutomation.org get access to the next generation of universal automation technology, working collaboratively within an ecosystem of innovative technology vendors and thought-leading users.

Plug & Produce

Application Portability & Interoperability

IT/OT Convergence

A new automation paradigm is required!

Traditional Automation world

IT Applications

Difficult

Proprietary

Control Node

Vendor 1

Vendor 2

Vendor 3

Vendor 4

- Locked to a vendor

- No portability & limited application interoperability

- Difficult to interface with IT systems

- Labor-intensive to engineer & operate

- Prevents innovation & evolution of installed base

IT Applications

Easy

Hardware independent Application

Universal Automation

Control Node

Controller

Runtime

Vendor 1

PLC

Controller

Runtime

Vendor 2

DCS

Controller

Runtime

Vendor 3

Instruments Actuators

Controller

Runtime

Vendor 4

Edge Computers

- More cost-effective – write once, re-use regardless of vendor

- More reliable & safer using proven-in-use, reusable software libraries

- Software can be incrementally improved over the lifecycle

- End-of-life proof – re-use software, even when automation hardware is obsolete

- Embed & reuse IP to protect competitive edge or to get better ROI on increasing software investment

They joined us

We joined UAO because we strongly believe that we have to decouple the application from the hardware.

The value of our automation is not in the hardware and (yet today) we design every plant in hardware-centric way. That is no longer possible with the regional complexities of cyber security, more maintenance, more complex software requirements. On our current path towards Industry 4.0 that hardware-centric approach no longer good. So in short, we must decouple hardware & software to make sure that we are able to survive as an industry in Europe.

Dominic de Kerf

Plant Systems and Controls COE

We are excited to be part of UniversalAutomation.org because it promises to be a complete game changer. It opens up a new world of possibilities for organisations like ours. Unlocking valuable data currently buried in proprietary systems, making the connectivity and deployment of new technologies like Artificial Intelligence quick and simple. As part of UniversalAutomation.org we are actively collaborating with and supporting like-minded organisations to create an exciting new open era in operations and automation.

Valeriy Vyatkin

Professor of Electrical Engineering at Aalto University

I think now is a great time to disrupt the industry, really become hardware agnostic and let the end user decide what hardware they want to use.

Customers can basically choose the hardware they want using just one automation platform, so they become very versatile and are not bound to one particular vendor.

Universal Automation provides precisely the level of flexibility that a competitive and sustainable industry requires. For our customers, this is exactly what they are looking for today.

Nicholas Holland

Managing Director - EMEA Broad Market

There is a huge room for improvement on the way runtimes are managed and orchestrated today. By joining UAO we aim to contribute to make large runtime deployments more scalable and secure through modern Edge Management functions. Our participation in UAO represents another significant step in our commitment to delivering open and flexible solutions based on industry standards, enabling industrial organizations to innovate more rapidly and with reduced risk.

David Purón

CEO and Co-founder at Barbara

As a university, we’re committed to preparing the future workforce by aligning our curriculum with industry needs. Our courses, developed in collaboration with industry partners, blend cutting-edge theory with practical experience. With Universal Automation leading the next wave of industrial transformation through IT convergence and digitalization, our membership empowers us to stay at the forefront and drive this change in Australia.

Dr. Octavian Bass

Senior Lecturer - Electrical Engineering

At our hydro plants, we’re modernizing technology from the 1950s. UAO’s IEC 61499 standard lets us decouple software from hardware and build reusable function libraries across assets. This shift to a function-first approach is a game-changer, and our teams quickly embraced it. We're excited to unify diverse machines and PLCs under one standard.

Laurent Bacon

Head of Industrial Information and Control

UniversalAutomation.org marks a new era in automation technology, set to transform software development over the next five years. We're proud to contribute to the “plug and produce” vision, supporting flexible manufacturing. As more members join and embrace collaboration and openness, industry-wide change is inevitable.

Dmitrii Drozdov

Chief Technology Officer at Flexbridge

I joined UAO because by being open, by being an international standard, by being already supported by quite a certain number of relevant companies, it paves the way for a new generation of not just automation systems, but a new way of conceiving automation systems. Because in the end it leaves behind the problem of hardware and unleashes the power of software, which has not yet happened in automation.

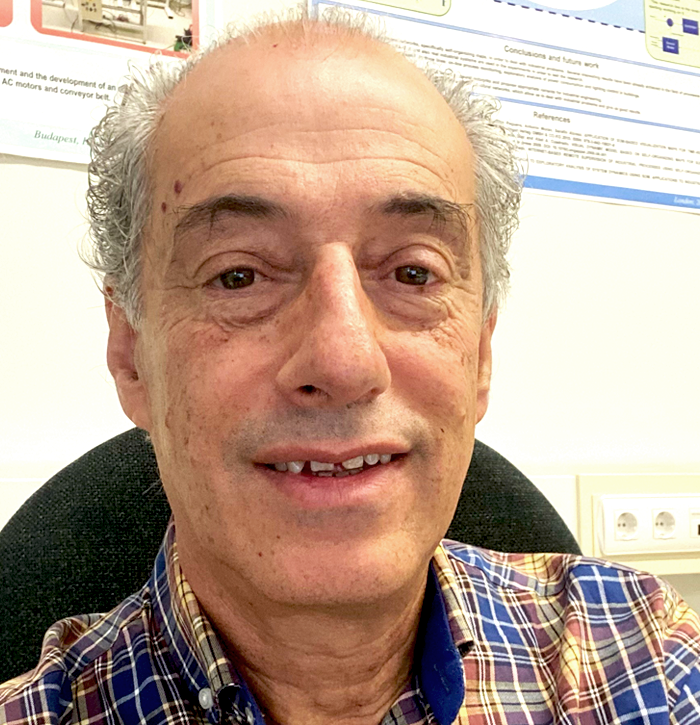

Franco Cavadini

Chief Technical Officer

As a teacher in Electrical Engineering, I believe it’s vital to expose students to future-ready technologies. Today’s hardware-centric automation limits flexibility and interoperability, making evolution costly and complex. In contrast, IEC 61499 enables software-centric, open automation that bridges OT and IT, supporting agile, data-driven industry needs. INSA Lyon joined UniversalAutomation.org to give students hands-on experience with this modern, interoperable approach.

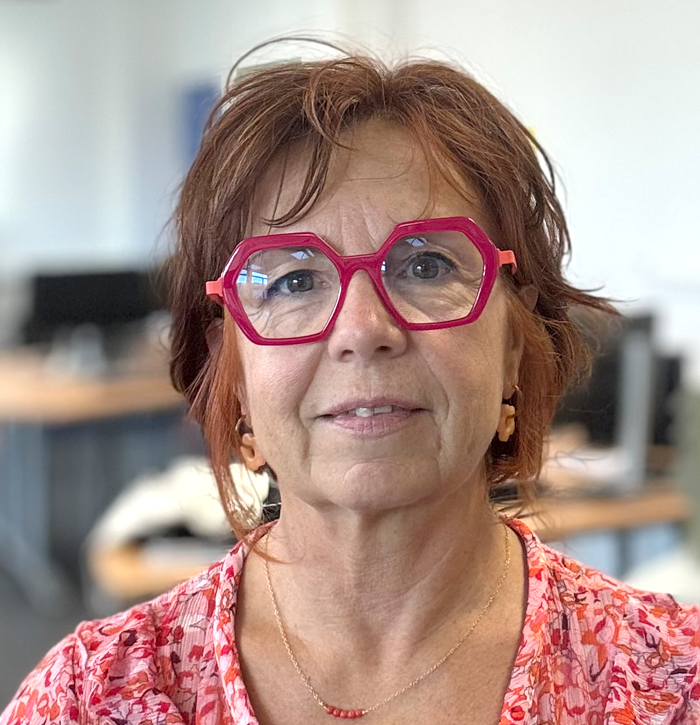

Mady Guillemot

Professor and Researcher

Joining UniversalAutomation.org provides the collaborative and open ecosystem we have been looking for to advance industrial automation.

With our work on IEC 61499 and the open-source project Eclipse 4diac, we aim to support the adoption of standards and technologies that enable seamless connectivity, data exchange, and innovation across industrial automation systems.

Dr. Alois Zoitl

Univ.-Prof. Johannes Kepler University Linz

We prefer systems built on open standards over vendor-locked solutions. IEC 61499 opens up our architecture and makes it future-ready, helping avoid obsolescence and giving us the freedom to choose the best vendors. UAO not only provides the standard—it delivers a robust implementation through a quality-driven, guarded-source community.

Sølve Raaen

Principal Architect OT

Our customers want open systems—and so do we. With IEC 61499, one interface works across all controllers, making integration easier and more flexible. You can mix systems across locations and they’ll still work together. While process automation has been conservative, a new tech-savvy generation is embracing change. After 20 years in the field, this is the most exciting shift I’ve seen.

Andre Fritsch

Senior Product Manager

Penguin Solutions is proud to support open, vendor-independent automation through UniversalAutomation.org. UAO’s open approach lets users choose the best hardware-software combinations, backed by reliable, secure platforms with virtualization and fault tolerance. Our membership helps businesses scale, innovate, and accelerate time to market across multi-vendor environments.

Rudy de Anda

Head of Strategic Alliances

At UFRN, joining Universal Automation reflects our commitment to advancing next-generation industrial automation. We see IEC 61499 as key to enabling openness and flexibility in industry, and our long-standing partnership with Smar strengthens this vision. Through this membership, we aim to drive innovation, connect academia with industry, and help shape the digital future.

André Maitelli

Professor

At the University of León, the SUPPRESS Research Group focuses on automation, control, and advanced monitoring of industrial processes. We integrate IEC61499 into our curriculum and apply data-driven strategies and industrial cybersecurity in our research to support the future of Universal Automation.

Manuel Domínguez González

Director of the SUPPRESS research group

I joined UniversalAutomation.Org to be part of a vibrant community that fosters collaboration between academia and industry. UAO offers a unique platform for networking, learning from global experts, and sharing our research and technical insights to help shape the future of open automation. It’s an exciting opportunity to contribute to a movement that values openness, innovation, and collective progress.

Mohsen Yahyaei

Professor

We operate several thousand third-party installations, so we find ourselves with a large volume of equipment from different brands. This requires great complexity of skills to maintain them. This is why the association’s approach interests us greatly: to simplify the multi-vendor complexity. Pooling the skills of our employees on a limited number of platforms is a guarantee of operational efficiency, and a vector of success for the dissemination of standards.

Michel Arroyo

Operations and Performance Director

Wood is excited to be part of defining the future of automation and transforming profitability and productivity for the customers in our industrial markets. UniversalAutomation.org technology will enable business innovation, increase digital adoption and agility with its open, interoperable and portable solutions- building business resiliency and empowering our clients to be future-ready.

German Carmona

Global President of Wood’s Digital Consulting business